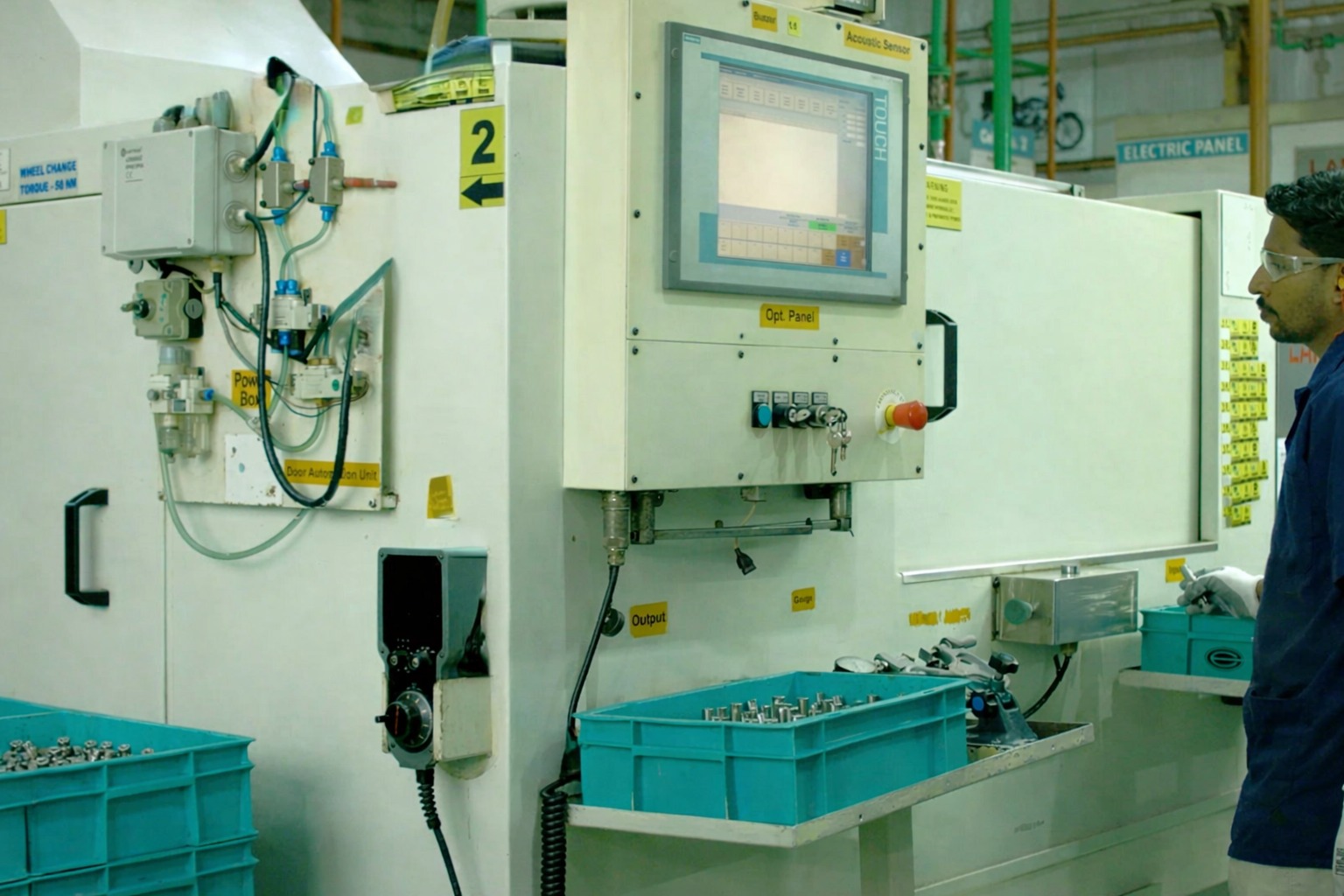

Our machine shop is equipped with the state of art CNC's, VMC's, HMC's, and specialized grinding machines for high-precision component manufacturing. Over 80% of our machines are imported, ensuring global standards in performance and reliability.

Delivers high-precision external grinding for small and medium-sized components, ensuring consistent dimensional accuracy for critical parts

Capable of grinding small, close-tolerance parts as well as components up to 400 mm length, 200 mm diameter, and 150 kg weight

Hydrodynamic spindle technology provides superior surface finish

Rigid MT5 workhead, tailstock, and V-Flat slide ensure vibration-free grinding and repeatable results across all part sizes

Powerful 11 / 15 kW wheel head spindle motor

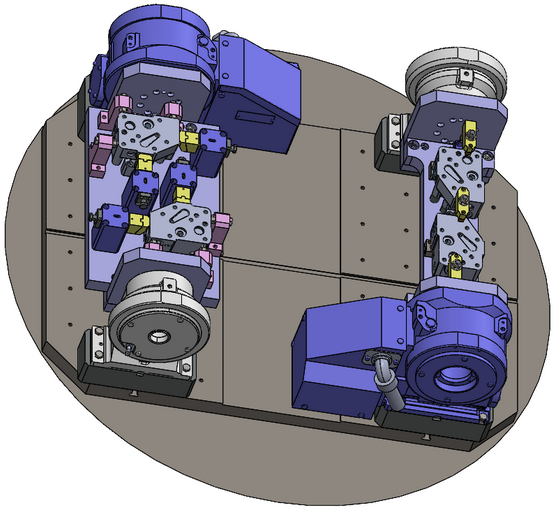

Simultaneous multi-spindle machining delivers higher productivity and reduced cycle time

Ensures consistent groove depth and profile accuracy across all components

Optimized clamping and tooling layout minimizes variation and ensures uniform results

Reduced manual intervention improves process reliability and operator safety

Designed for continuous and high-volume production environments

Achieves taper and ovality within 0.003 microns (max) for ultra-precision bores

Single-pass honing process ensures stable geometry and uniform surface finish

Multiple parts processed in one cycle, significantly improving throughput

Self-centering system guarantees consistent alignment and repeatable accuracy

Low cycle time compared to conventional multi-pass honing processes

14,000 MT/Year

Up to 900 × 700 × 1000 mm

5–300 kg

1,200 MT/Year

Up to 10 lbs

150T – 500T

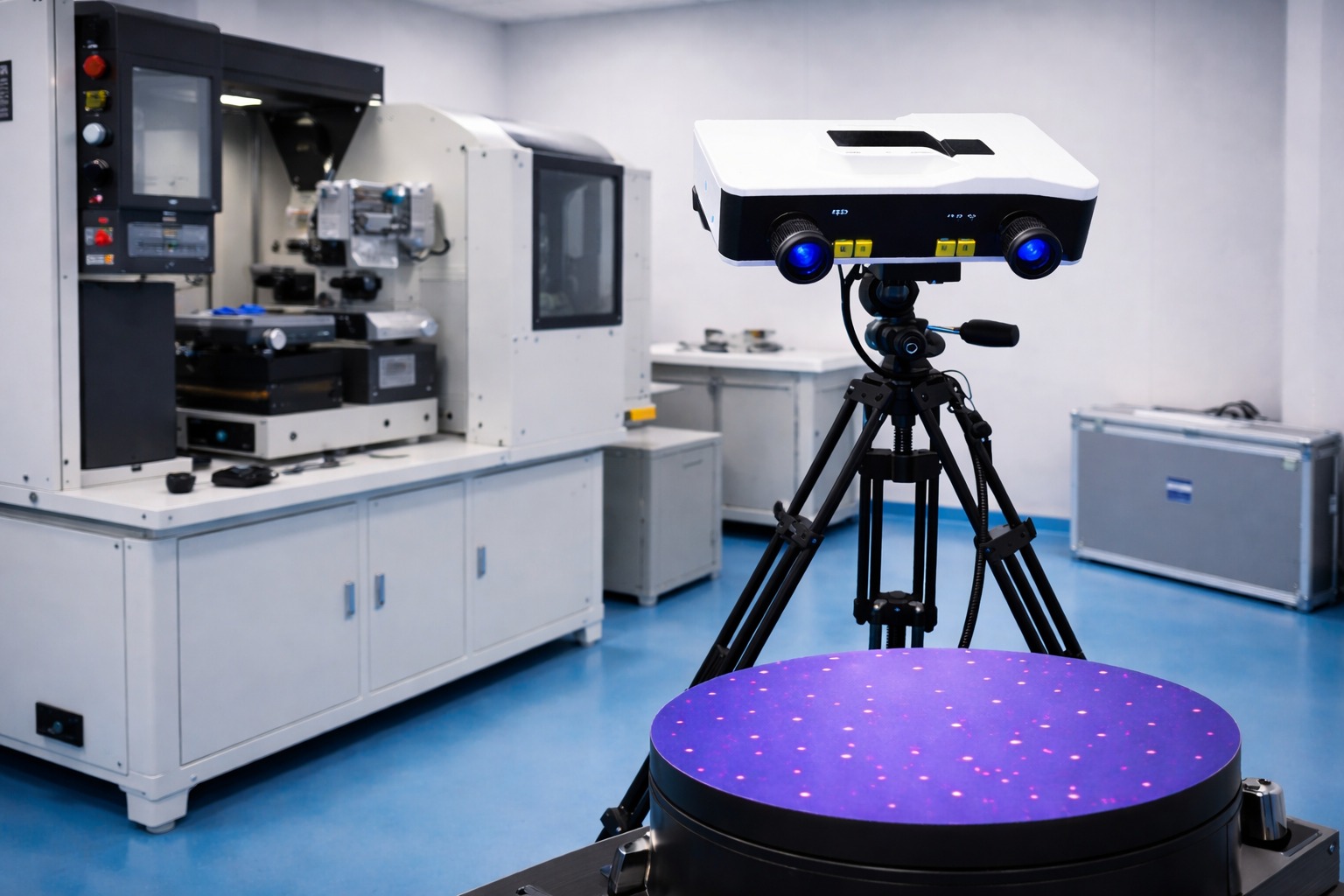

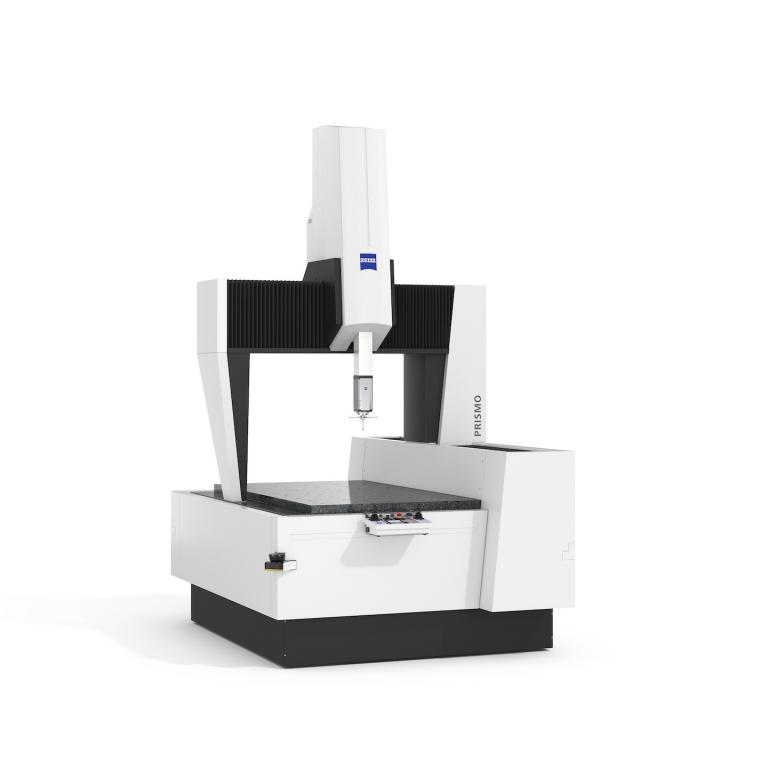

To uphold its exceptional quality standards, we operate cutting edge laboratories providing comprehensive metallurgical testing capabilities for raw materials, inprocess and finished parts

Dimensional & Geometric Accuracy

Material & Metallurgical Validation

Cleanliness & Process Reliability

Our advanced machining shops combine next-generation CNC technology with robotic automation for loading, unloading and material handlling.

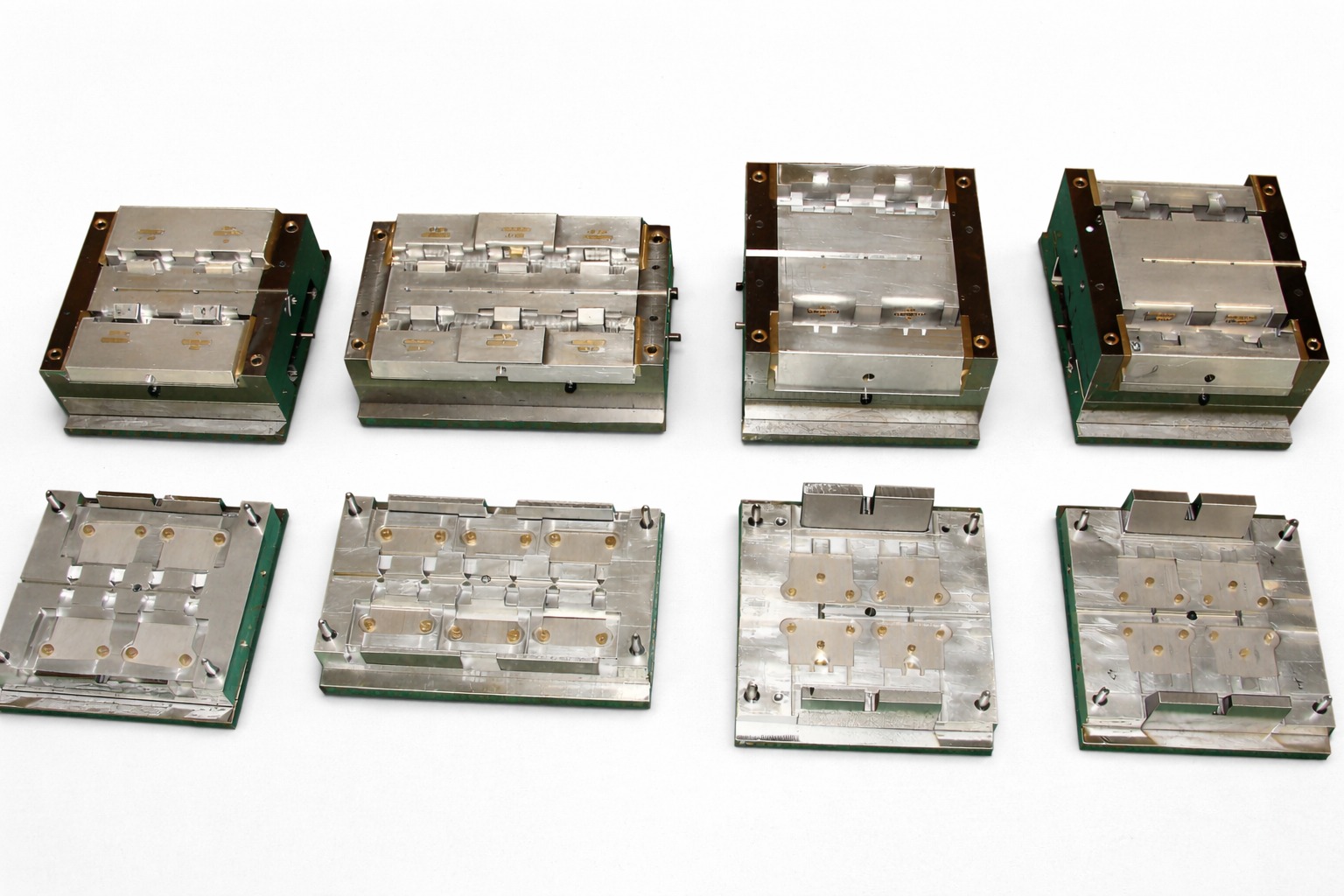

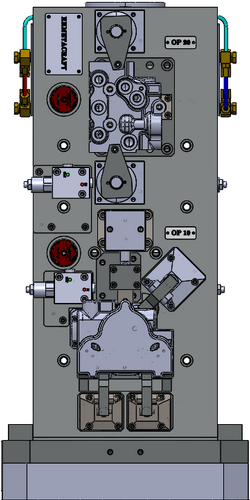

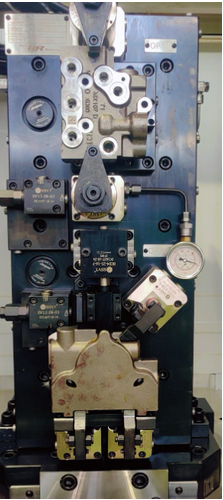

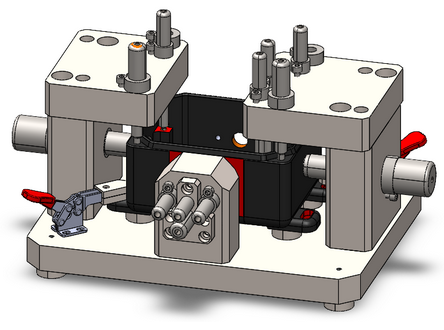

We specialize in the design and manufacture of high-precision fixtures tailored to meet the demands of various industries including automotive, aerospace, electronics, and medical devices. Each fixture is engineered to ensure accuracy, repeatability, and ease of use—helping our clients streamline production and achieve consistent quality.

500 T/Year

Up to 800 mm × 800 mm